Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

Mortar spraying pump

Classification:

Key words:

construction machinery

Product Details

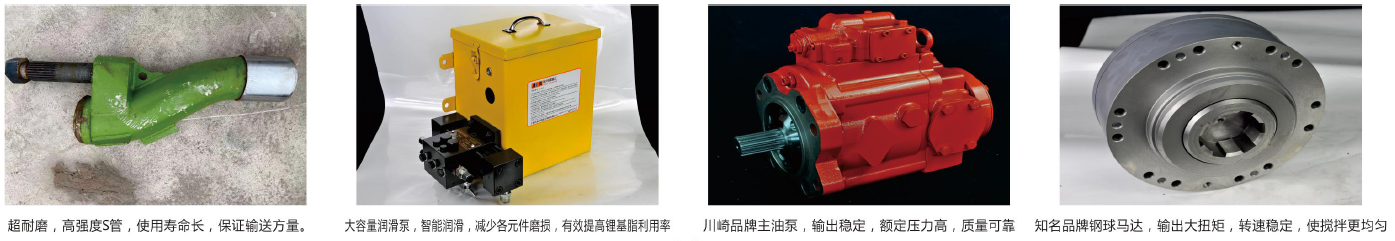

The series of mortar spraying pumps independently developed by Saner Heavy Industry adopts a new generation of S-pipe valves to reverse direction, and is equipped with floating wear-resistant rings to automatically compensate for wear. The outlet pressure is high, which can meet the high-level transportation, and has the anti-pump function to minimize pipeline blockage.

The hydraulic system adopts air cooling to reduce water pollution and is equipped with an automatic lubrication system to effectively extend the service life of rotating parts.

The operating system is equipped with wireless remote control and panel control, which can be switched to each other. The remote control distance can be as high as 200m or more, and has the characteristics of good penetration. The screen mesh can be disassembled as a whole for easy replacement. 360 ° guided movement, flexible and convenient positioning.

Product advantages

1, strong mobility, the equipment structure is simple, lightweight, mobile positioning convenient, changed the traditional field scattered mixing small production mode, and can solve the construction site narrow, difficult to pile the problem.

2. The degree of mechanized construction is high, which reduces the labor intensity.

3. Conveying and pouring of concrete are carried out continuously, with high construction efficiency and fast project progress.

4. The pumping process has strict requirements on the quality of concrete and is easy to ensure the quality of the project.

5. It can reduce the dust, waste water, mud and other environmental pollution existing in the field mixing, and realize the civilized construction.

6, hydraulic double cylinder piston reciprocating conveying, hydraulic system structure is simple, easy to operate.

7, S pipe distribution valve swing resistance is small, switching quickly, can achieve uninterrupted concrete spraying.

Product Parameters

| Product Name |

Product Model |

Product abbreviation |

Product Name |

Product Model |

Product abbreviation |

||

| mortar spraying pump |

SR0810UBD |

V8 |

mortar spraying pump |

SR0810UBC |

V8C |

||

| Serial Number |

One. Whole machine parameters |

Serial Number |

One. Whole machine parameters |

||||

| 1 |

Overall size (mm) |

4580 × 1730 × 1960 |

1 |

Overall size (mm) |

4580 × 1730 × 2330 |

||

| 2 |

Rated weight (kg) |

3500 |

2 |

Rated weight (kg) |

4000 |

||

| 3 |

Nozzle form |

None |

3 |

Nozzle form |

None |

||

| 4 |

Distribution valve form |

S valve |

4 |

Distribution valve form |

S valve |

||

| 5 |

Maximum vertical conveying distance (m) |

90 |

5 |

Maximum vertical conveying distance (m) |

90 |

||

| 6 |

Maximum horizontal conveying distance (m) |

200 |

6 |

Maximum horizontal conveying distance (m) |

200 |

||

| Serial Number |

2 pumping parameters |

Serial Number |

2 pumping parameters |

||||

| 1 |

Working driving mode |

three-phase asynchronous motor |

1 |

Working driving mode |

Diesel engine |

||

| 2 |

Motor rated power (kw) |

37 |

2 |

Rated power of diesel engine (kw) |

45.8 |

||

| 3 |

Motor working voltage (V) |

380 |

3 |

Output voltage of diesel engine (V) |

24 |

||

| 4 |

Motor rated speed (Rpm) |

1475 |

4 |

Rated speed of diesel engine (Rpm) |

1800 |

||

| 5 |

Hopper volume (m³) |

0.4 |

5 |

Hopper volume (m³) |

0.4 |

||

| 6 |

Concrete displacement (m³/h) |

8 |

6 |

Concrete displacement (m³/h) |

8 |

||

| 7 |

Delivery cylinder bore × stroke (mm) |

Ø140 × 1085 |

7 |

Delivery cylinder bore × stroke (mm) |

0140 × 1085 |

||

| 8 |

Main cylinder bore × stroke (mm) |

090 × 055 × 1000 |

8 |

Main cylinder bore × stroke (mm) |

090 × 055 × 1000 |

||

| 9 |

Maximum system pressure (Mpa) |

26 |

9 |

Maximum system pressure (Mpa) |

26 |

||

| 10 |

Concrete outlet pressure (Mpa) |

10 |

10 |

Concrete outlet pressure (Mpa) |

10 |

||

| 11 |

Maximum particle size of concrete (mm) |

8 |

11 |

Maximum particle size of concrete (mm) |

8 |

||

| 12 |

Feeding height (mm) |

≤ 1400 |

12 |

Feeding height (mm) |

≤ 1400 |

||

| 13 |

Variable diameter form (mm) |

0125/0100 → 080 → 050 |

13 |

Variable diameter form (mm) |

0125/0100 → 280 → 050 |

||

| 14 |

Concrete slump (mm) |

50-120 |

14 |

Concrete slump (mm) |

50-120 |

||

| 15 |

Diameter of conveying pipe (mm) |

80 |

15 |

Diameter of conveying pipe (mm) |

② 80 |

||

| 16 |

Lubrication system |

Lubrication pump, progressive oil separator |

16 |

Lubrication system |

Lubrication pump, progressive oil separator |

||

| Serial Number |

4 Walking mode |

Serial Number |

4 Walking mode |

||||

| 1 |

Drive form |

Vehicle transportation or ≤ 4 km/h hauling |

1 |

Drive form |

Vehicle transportation or ≤ 4 km/h hauling |

||

Online consultation