Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

SRZY200E Curved-Arm Rock Drilling Rig

Classification:

Key words:

Product Details

The SRZY200E Two-Arm Tunnelling and Rock Drilling Rig is a brand-new, intelligent, high-end rock drilling equipment independently developed and manufactured by our company. Specifically designed for construction projects such as highway tunnels, main tunnels for high-speed railways, inclined shafts, cross-cuts, and pilot drifts, this product effectively addresses the traditional drill rig's limited adaptability to varying tunnel cross-sections, enabling it to achieve "multi-purpose functionality" in a single machine. Capable of handling all types of working conditions, the rig excels at drilling high up, reaching deep downward, extending far forward, and covering wide lateral areas—making it suitable for various bench configurations, including micro-benching, two-bench systems, three-bench systems (including the core-soil method), and inverted arches. It’s ideal for advancing excavation operations. For full-face tunnel construction, using two rigs simultaneously delivers outstanding results. Equipped with dual rotating reducer booms, the rig ensures superior control and enhanced efficiency during anchor bolt installation. Additionally, the electrical system features imported-brand components and an IP67-rated controller that provides precise output control while offering advanced protection mechanisms such as overcurrent, overload, phase failure, and overheating safeguards—all contributing to improved energy efficiency and heightened operational safety.

It employs hydraulic cylinders from world-class manufacturers, ensuring reliable performance and superior functionality of the hydraulic system. Equipped with a four-wheel-drive engineering vehicle chassis, it guarantees excellent tire contact even on rugged terrain, offering outstanding road adaptability, rapid relocation capabilities, and exceptional climbing ability. The machine features a two-speed forward and two-speed reverse hydrostatic transmission system, renowned for its high reliability and ease of operation—perfect for swift movement across flat surfaces—and allows for quick, automatic switching between two distinct operating modes: one optimized for high torque during uphill climbs, while the other ensures efficient, high-speed travel on level ground. Additionally, it is fitted with a 18kW WORTHED-brand hydraulic rock drill boasting world-class power output, complemented by a dual-buffer system that reduces consumable wear by up to 30% compared to single-buffer systems. Its high-frequency, high-pressure impact design delivers unmatched explosive force, making it particularly well-suited for working in hard-rock environments such as mines and quarries. This results in exceptional operational efficiency, delivering powerful drilling performance with significant rotational torque, enabling rapid hole penetration and boosting overall construction productivity. Finally, the machine incorporates imported alloy materials throughout its moving components, ensuring superior lubrication levels, ample mist-lubrication coverage, and an advanced oil-air interface system at both end faces.

The entire vehicle drilling operation is conducted entirely via remote control, allowing real-time monitoring of construction conditions, ensuring precise positioning, smooth movements, and high feasibility.

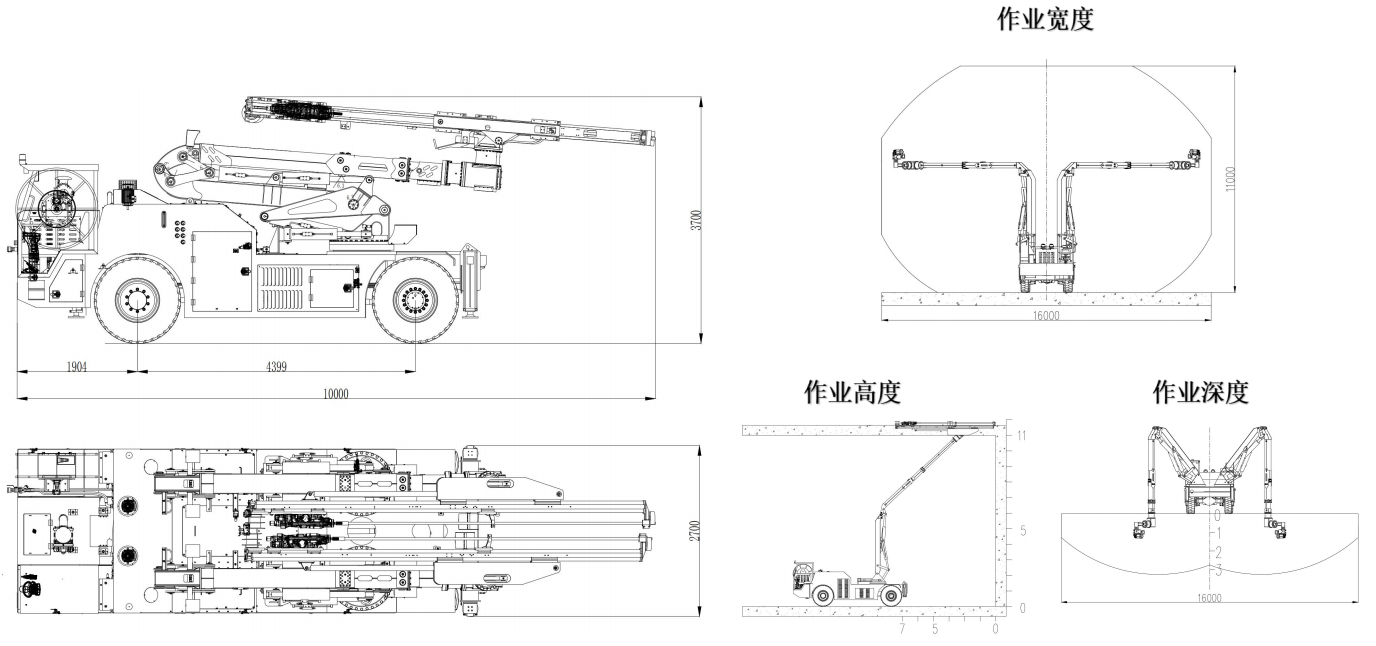

Product external dimensions

1. The vehicle is equipped as standard with a 70-meter-long, highly tensile and abrasion-resistant cable, featuring automatic retraction and extension for flexible and rapid equipment deployment in and out of the site.

2. All whole-vehicle drilling operations are performed using a remote control, enabling real-time monitoring of the construction process, precise positioning, smooth movements, and high reliability.

3. Utilizing hydrodynamic transmission, the electronically controlled power system eliminates the need to stop for gear changes, making operation more convenient and ensuring greater stability in vehicle performance.

4. Equipped with an 18KW effective-power hydraulic rock drill, this machine delivers high operational efficiency, powerful impact force, and substantial rotational torque, enabling rapid drilling and significantly boosting the overall construction efficiency of the vehicle.

5. It features a semi-enclosed cab with wide visibility, ensuring a high level of operational safety and meeting FOPS (Falling Object Protective Structure) standards.

6. The aluminum alloy propeller is highly adaptable, delivers strong thrust, is easy to operate, boasts excellent stability, and requires low maintenance costs.

7. Equipped with automatic anti-jamming function and an automatic lubrication system, it delivers fast drilling speeds while minimizing bit consumption.

8. Four heavy-duty hydraulic outriggers, featuring an H-shaped outrigger design at both the front and rear, ensure exceptional mobility while maintaining a remarkably robust "chassis" during rock drilling operations.

9. The electrical system features imported brand components, with an IP67-rated controller managing the output. It includes advanced protection mechanisms such as overcurrent, overload, phase-loss, overheating, and waterproof functions, ensuring enhanced energy efficiency and superior safety.

Product Specifications

| Project Name |

Specification Model |

Parameters |

| Complete machine |

Product Model |

SRZY200E |

| External dimensions mm |

10000×2700×3700 |

|

| Adaptation section (width × height) m |

16X11 |

|

| Rock drill |

1838 ME/Vosde |

|

| Rock-drilling diameter mm |

Φ45-76 |

|

| Drill rod length mm |

4900/5525 |

|

| Drilling depth mm |

4600/5200 |

|

| Anchorage bar length and number |

Drilling speed: 0.8–2 m/min |

|

| Main motor power: KW |

55/75 |

|

| Hydraulic oil tank volume: L |

250 × 2 |

|

| Total weight kg |

28500 |

|

| Drill arm |

Boom configuration |

Folding Arm |

| Rotational Swing Angle |

-5.45 ° |

|

| Extension stroke mm |

2200 |

|

| Upper Arm Pitch Angle |

133° |

|

| Working arm pitch angle |

48° |

|

| Propeller pitch |

Propeller pitch angle: -5° to 45° |

|

| Propeller compensation mm |

1800 |

|

| Chassis |

Engine power kW |

110 |

| Turning |

Inner steering 25°, outer steering 27° |

|

| Tire |

14.00R24 |

|

| Maebashi Leg Swing |

±7 ° |

|

| Approach Angle / Departure Angle |

17 °/15 ° |

|

| Minimum turning radius m |

Outer 11.5 / Inner 5.65 |

|

| Walking speed km/h |

15 |

|

| Climbing ability (%) |

15° |

|

| Minimum ground clearance mm |

380 |

|

| Service brake |

Hydraulic braking |

|

| Fuel tank capacity: L |

110 |

|

| Gas Supply System |

Displacement L/min |

970 |

| Working pressure MPa |

0.2–0.8 |

|

| Motor power kW |

7.5 |

|

| Water Supply System |

Displacement L/min |

170 × 2 |

| Working water pressure MPa |

0.8–1.2 |

|

| Motor power kW |

3 × 2 |

|

| Electrical System |

Total input power in kW |

2 × 55 + 7.5 + 6 |

| Voltage v |

380/660 |

|

| Cable reel m |

70 |

|

| Work light |

4 × 70W |

|

| Driving lights |

8 × 48W |

Note: Due to varying customer needs, our company reserves the right of final interpretation regarding the above content.

Device View / Job Scope

Online consultation