Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

Mining water truck

Classification:

Key words:

Product Details

The SRFC10 Mine Safety Model CY3000L water truck is primarily designed for underground watering applications, featuring a professionally engineered chassis. Powered by a diesel engine, it boasts exceptional adaptability. The vehicle excels in high impact resistance, low fuel consumption, minimal overall operating costs, and ease of operation, while also offering comfortable seating and a well-organized, user-friendly design that simplifies maintenance and upkeep.

Key electrical components—such as the controller, hydraulic system, and critical parts of the transmission—are sourced from renowned domestic and international brands, ensuring reliable performance. Additionally, the braking system employs advanced wet brakes combined with spring-loaded mechanisms and hydraulic release, further enhancing safety.

The cab is fully sealed and equipped with air conditioning, helping to reduce airborne dust and other harmful substances in the mine, thereby creating a healthier working environment for employees. This model is also ideally suited for use in cold and frigid conditions, capable of storing up to 3 cubic meters of water per fill-up.

Product Features

1. The cab provides drivers and passengers with excellent visibility and a comfortable cabin environment. The cabin is designed for safe, convenient entry and exit. The dashboard is simple and easy to use. Additionally, the enclosed cabin ensures a noise level below 75 decibels, guaranteeing both safety and driving comfort.

2. The entire vehicle coating employs shot blasting for rust removal, combined with a military-grade aircraft carrier anti-rust primer, ensuring superior rust and corrosion resistance under various operating conditions—and significantly extending the equipment's service life.

3. A scientifically and rationally designed structural configuration meets the operational requirements of various mine conditions, including underground tunnel turning radii, gradient inclines, and safe passage for mining operations. Notably, the dedicated chassis, fully sealed wet-axle drive system, and their advanced, matching braking system ensure safety, stability, and reliability—placing this technology at the forefront of its field.

4. Utilizing high-strength structural steel stamping, Haokeng stress aging technology, and gas-shielded welding techniques, the vehicle’s structural components have undergone rigorous strength verification and are capable of withstanding heavy loads.

5. The braking system and other components all utilize products from reputable domestic and international brands, ensuring reliable quality and performance, high safety standards, energy efficiency, reduced consumption, and smooth operation.

6. One-time watering of 3,000 liters reduces the number of water transport trips.

7. Suitable for high-altitude, low-temperature application scenarios (operating in harsh environments down to -40°C)

Product Specifications

| Trackless Mine Watering Truck Technical Specifications | |

| Product Name | Mining water truck |

| Product Applications | A self-propelled multi-purpose vehicle designed for water-spraying operations in mines. |

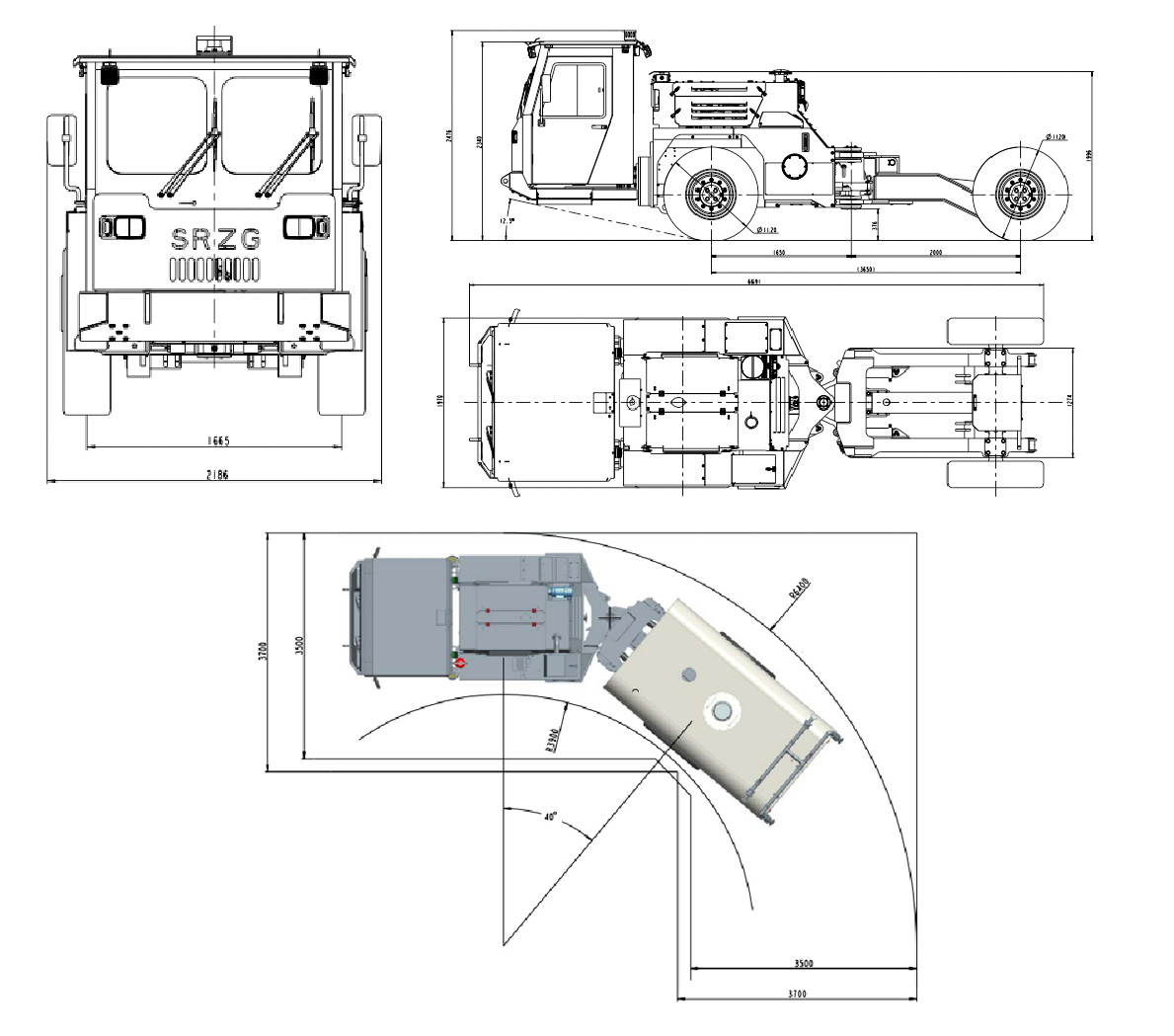

| External dimensions (L × W × H) (mm) | 6691*1970*2476 |

| Water tank volume (m³) | 3 |

| Cab | Enclosed cab with soundproofing design. The cockpit dimensions for the driver and passenger should comfortably accommodate a person up to 180 cm tall—two seats. |

| The glass of the cab | Three-layer laminated glass is required, and the glass for the cab's front windshield and side windows must be equipped with a ventilation system. |

| Seat | Adjustable driver's seat equipped with shock absorbers and a seatbelt. Includes an additional passenger seat. |

| External/Internal Turning Radius (mm) | 6400 / 3900 |

| Frame | Articulated frame, articulated steering system, rear axle fixed, front axle pivoting. Equipped with a linkage locking mechanism. Towing hooks are provided at both the front and rear. |

| Engine | Cummins diesel engine. |

| Engine power | 120 kilowatts |

| Cooling system | Liquid cooling |

| Tire | Single tire, pneumatic tire, suitable for rocky ores, with specifications of 10.00 x 20 |

| Bridge | Jin Zhitong (Henan Gengchi) front axle is tiltable by +/-10°, while the rear axle is fixed. |

| Transmission | Aerospace-grade powertrain with a power-shift transmission system—20,000 units. All-wheel drive. Three forward gears and one reverse gear. |

| Walking Brake | Hydraulic dual-circuit braking system, equipped with oil-immersed disc brakes, acting on both axles |

| Handbrake System | Equipped with a hydraulic release mechanism for normal braking |

| Steering System | Hydraulic steering system designed for articulated frames, Eaton |

| Hydraulic System | The hydraulic system features a variable-displacement axial piston pump, with an oil tank capacity of 130 liters. It is equipped with an electric fueling pump (24V), a breather valve, return and suction filters, as well as level, filtration, and temperature monitoring functions. |

| Electrical equipment | The operating voltage is 24 volts. |

| Waste Gas Purification System | Catalytic Neutralizer |

| Tire | 14:00–25 |

Online consultation