Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

Concrete on-board pump

Classification:

Key words:

construction machinery

Product Details

With the rise of modern industry, the construction mode of concrete as the main material has become one of the main structures in the construction industry, which occupies a large proportion in the construction of various projects, making the development of concrete machinery enduring, and there is an increasingly fierce situation. Concrete pumps are used for conveying and pouring work in concrete construction. The special concrete pump for tunnel produced by Saner Heavy Industry is specially designed to adapt to the characteristics of the construction of the second lining of the tunnel. It is equipped with a special pipeline, which can continuously complete horizontal and vertical transportation of concrete along the pipeline. It is an ideal equipment for existing concrete transportation. The use of large cylinder diameter, long stroke cylinder, to ensure that the construction distance is the highest, farther, the use of double pump, double circuit open hydraulic system, so that the system is simple, component life extension, higher reliability, and easy to fault judgment and troubleshooting. Glasses plates, cutting rings and other damaged parts, after continuous technical research, long service life. The outstanding concrete pump electric control system has the characteristics of mature technology, stable system, large pumping volume, convenient movement, long barrier-free working hours, and low maintenance costs.

Product Features

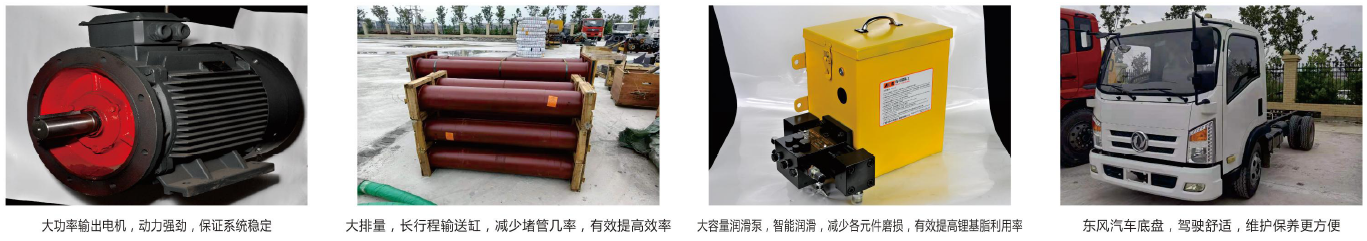

Power system: using domestic well-known brand three-phase motor, high efficiency, energy saving, good performance, low vibration, low noise, long life, high reliability, convenient maintenance, large starting torque.

Control system: the use of well-known brand controller, remote control, with overload protection short circuit protection, high quality and reliable accuracy, safe use.

Pumping system: large-capacity, high-strength hopper, large-displacement long-stroke conveying cylinder, good suction performance, high efficiency, long conveying distance, and low requirements for conveying media.

Hydraulic system: South Korea or Japan Kawasaki brand main oil pump, domestic famous brand valve group, economical, safe and reliable.

Chassis system: high-quality Dongfeng automobile chassis, strong load capacity and climbing ability, comfortable driving, easy operation, and guaranteed after-sales service.

Product advantages

1. The use of Dongfeng automobile chassis can quickly evacuate and transfer, saving time and improving work efficiency.

2. Equipped with a special wear-resistant pipeline, the concrete is continuously transported horizontally and vertically along the pipeline.

3. Adopt large cylinder diameter and long stroke cylinder to ensure the highest and farther construction distance. Adopt double pump and double circuit open hydraulic system.

4. The system is simple, the component life is extended, the reliability is higher, and it is easy to judge and eliminate the fault.

5, glasses plate, cutting ring and other wear parts, after continuous technical research, long service life.

6. The concrete pump electric control system is outstanding, with mature technology, stable performance and reliable quality.

7, barrier-free working hours, low maintenance costs and other characteristics.

Product Parameters

| Serial Number | I. Overall Machine Parameters | ||||

| 1 | Overall size (mm) | 7500 × 2150 × 2400 | |||

| 2 | Rated weight (kg) | 7700 | |||

| 3 | Nozzle form | None | |||

| 4 | Distribution valve form | S pipe distribution | |||

| 5 | Maximum vertical conveying distance (m) | 115 | |||

| 6 | Maximum horizontal conveying distance (m) | 300 | |||

| Serial Number | 2 pumping parameters | ||||

| 1 | Working driving mode | three-phase asynchronous motor | |||

| 2 | Motor rated power (kw) | 75 | |||

| 3 | Motor working voltage (V) | 380 | |||

| 4 | Motor rated speed (Rpm) | 1475 | |||

| 5 | Hopper volume (m3) | 0.8 | |||

| 6 | Concrete displacement (m3/ h) | 64 | |||

| 7 | Delivery cylinder bore × stroke (mm) | Ø230 × 1565 | |||

| 8 | Main cylinder bore × stroke (mm) | Ø140 × Ø 90 × 1400 | |||

| 9 | Maximum system pressure (Mpa) | 32 | |||

| 10 | Concrete outlet pressure (Mpa) | 12 | |||

| 11 | Maximum particle size of concrete (mm) | 40 | |||

| 12 | Feeding height (mm) | ≤ 1450 | |||

| 13 | Variable diameter form (mm) | Ø180 → Ø150 → Ø125 | |||

| 14 | Concrete slump (mm) | 160-230 | |||

| 15 | Diameter of conveying pipe (mm) | Ø125 | |||

| 16 | Lubrication system | Lubrication pump, progressive oil separator | |||

| Serial Number | 4 Engineering chassis parameters | ||||

| 1 | Drive form | Diesel engine | |||

| 2 | Engine power (kw) | 66.2 | |||

| 3 | Wheelbase (mm) | 3360 | |||

| 4 | Wheel track of front axle (center of wheel width mm) | 1584 | |||

| 5 | Rear axle track (center of wheel width mm) | 1540 | |||

| 6 | Tires | 7.00R16 | |||

| 7 | Front/rear axle load (T) | 2.64/4.72 | |||

| 8 | Maximum speed (km/h) | 60 | |||

| 9 | Maximum climbing angle (³) | 15 | |||

| 10 | Minimum turning radius (m) | 7 | |||

Online consultation