Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

A7 vehicle-mounted double-nozzle wet spraying machine

Classification:

Key words:

construction machinery

Product Details

Wet spraying machine is widely used in hydropower tunnel, underground plant, subway engineering, railway tunnel, military underground engineering and highway engineering and other construction fields. Compared with dry spraying, wet spraying technology has the advantages of high production efficiency, low resilience and guaranteed engineering quality, creating a new model of green environmental protection construction.

The wet spraying machine developed by Hunan Saner Heavy Industry Zibao is divided into towed wet spraying machine, vehicle-mounted wet spraying machine and engineering concrete wet spraying machine with high degree of automation. It has the advantages of simple structure, strong adaptability, high delivery pressure, long conveying distance, high efficiency, high performance, high reliability, [low rebound, convenient movement and other excellent characteristics, and is a good helper for tunnel wet spraying engineering.

The wet spraying machine series products independently developed by Hunan Saner Heavy Industry have been successfully applied in major projects such as Qianyun High-speed Railway, Shaanxi High-speed Railway, Shanghai-Kunming Tunnel, Quning High-speed Railway, etc., which provides reliable guarantee for the improvement of project progress and quality.

Product Features

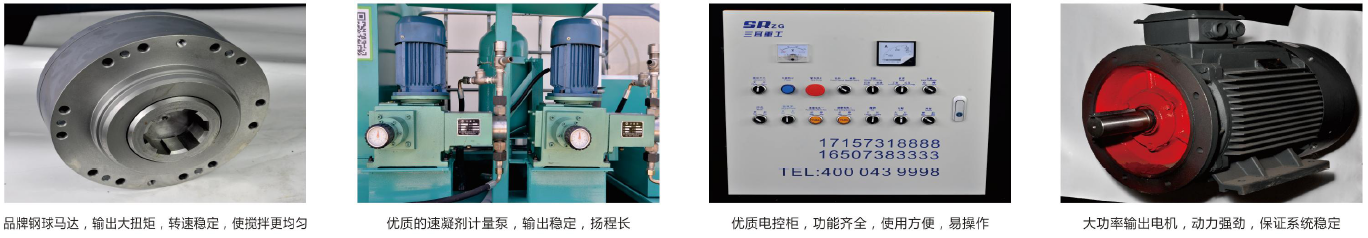

Accelerator system: the use of domestic well-known brands of fast coagulant metering pump, stable flow, long lift distance, simple maintenance, reliable quality, cost savings.

Control system: imported and well-known brand controller, remote diagnosis and remote control, the system comes with overload protection short circuit protection, high quality and reliable accuracy, safe use.

Pumping system: high-strength and high-quality hopper, long-stroke conveying cylinder, good suction performance, high efficiency, long conveying distance, not affected by road conditions.

Hydraulic system: South Korea or Japan Kawasaki brand main oil pump, domestic famous brand valve group, economical, safe and reliable.

Chassis system: self-made engineering vehicle chassis, simple structure, mechanical transmission, maintenance and more convenient.

Product advantages

1. The equipment structure is simple, with walking engineering chassis, convenient transition and strong adaptability.

2. High efficiency: high pumping pressure, long conveying distance, large conveying displacement and high comprehensive work efficiency.

3. High performance: Shotcrete has high performance, compactness, homogeneity and high strength.

4. High reliability: The key parts adopt domestic well-known brands to ensure high reliability of the equipment.

5. Low rebound degree. When dry spraying, the concrete rebound of 15%-50%, the use of wet spraying technology, the rebound rate can even be reduced to less than 10%, effective cost savings.

Product Parameters

| Serial Number | I. Overall Machine Parameters | ||||

| 1 | Overall size (mm) | 6500x2250x2350 | |||

| 2 | Rated weight | About 7.5T | |||

| 3 | Nozzle form | double nozzle | |||

| 4 | Distribution valve form | S tube | |||

| 5 | Maximum vertical spray distance (m) | 25 | |||

| 6 | Maximum horizontal spray distance (m) | 35 | |||

| Serial Number | 2 pumping parameters | ||||

| 1 | Working driving mode | three-phase asynchronous motor | |||

| 2 | Motor rated power | 45KW | |||

| 3 | Motor operating voltage | 380V | |||

| 4 | Hopper volume | 0.5m³ | |||

| 5 | Concrete displacement | 25m³/h | |||

| 6 | Pumping package | Full package | |||

| 7 | Conveying cylinder bore × stroke | Ф 160 × 1000mm | |||

| 8 | Main cylinder bore × stroke | F100 × F70 × 1000mm | |||

| 9 | Maximum system pressure | 26Mpa | |||

| 10 | Concrete outlet pressure | 10Mpa | |||

| 11 | Maximum particle size of concrete (mm) | ≤ 16 | |||

| 12 | Feeding height (mm) | ≤ 1400 | |||

| 13 | Maximum theoretical displacement of accelerator pump | 270L/H × 2 sets | |||

| 14 | Maximum outlet pressure of accelerator pump | 1.1Mpa | |||

| 15 | Conveying pipe diameter | Ф 125-Φ 100mm ,Ф 100-Φ57mm reducer | |||

| 16 | Nozzle diameter | F45mm | |||

| Serial Number | Four. Engineering chassis parameters | ||||

| 1 | Drive form | Rear drive | |||

| 2 | Engine power | 46Kw | |||

| 3 | Wheelbase | 2800mm | |||

| 4 | Front axle track (center of wheel width) | 1750mm | |||

| 5 | Rear axle track (center of wheel width) | 1650mm | |||

| 6 | Tires | 7.50R16 | |||

| 7 | Front/rear axle load | 2.5T/5.5T | |||

| 8 | Top speed | 40km/h | |||

| 9 | Maximum climbing angle | 20° | |||

| 10 | Minimum turning radius | 7m | |||

Online consultation