Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

Mining Wet Spray Machine

Classification:

Key words:

Product Details

The SRSP-20TJ Mine Concrete Spraying Vehicle, certified by the Mine Safety Administration under model number UPS20J, is a brand-new, compact wet spraying equipment designed specifically for underground mining applications. It features an advanced concrete wet-spraying robotic arm, developed exclusively to address the challenges of wet spraying support systems in mines. This equipment significantly outperforms traditional methods in terms of production efficiency and rebound control, thanks to its high-pressure, close-range spraying technology that elevates spraying quality to a whole new level. Widely used in underground mines or small-to-medium-sized underground construction projects for wet spraying and concrete support operations, the vehicle boasts a diesel-engine-powered four-wheel-drive system and a tire-articulated chassis for agile, rapid relocation. It can easily navigate slopes of up to 20°. Additionally, the machine is equipped with its own integrated air compressor and quick-setting agent addition system, along with remote-control capabilities, ensuring both safety and high efficiency during operation.

Product Features

High efficiency: Piston-type pumping system with a maximum injection rate of up to 20 m³/h;

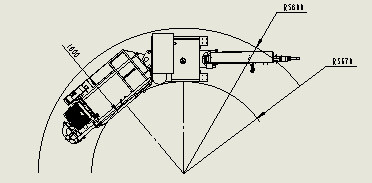

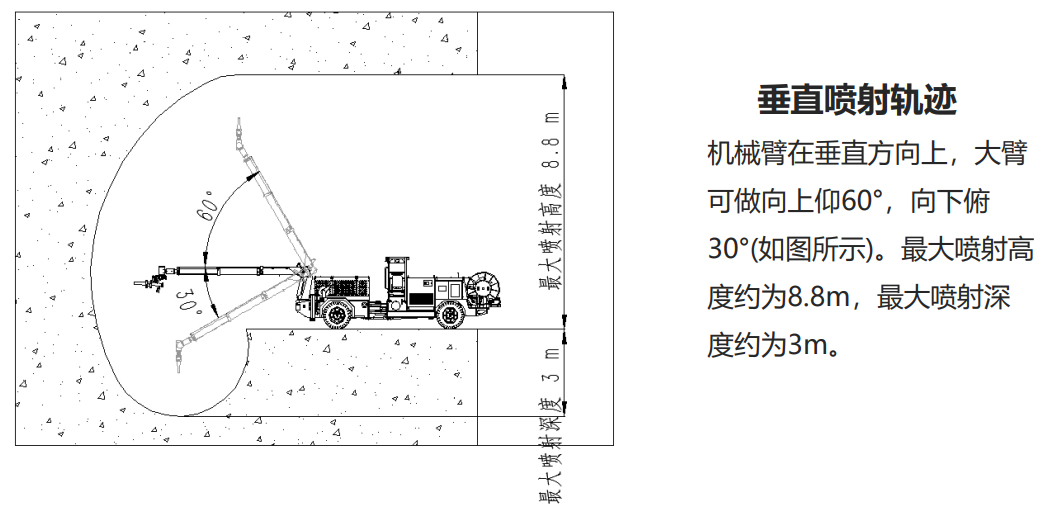

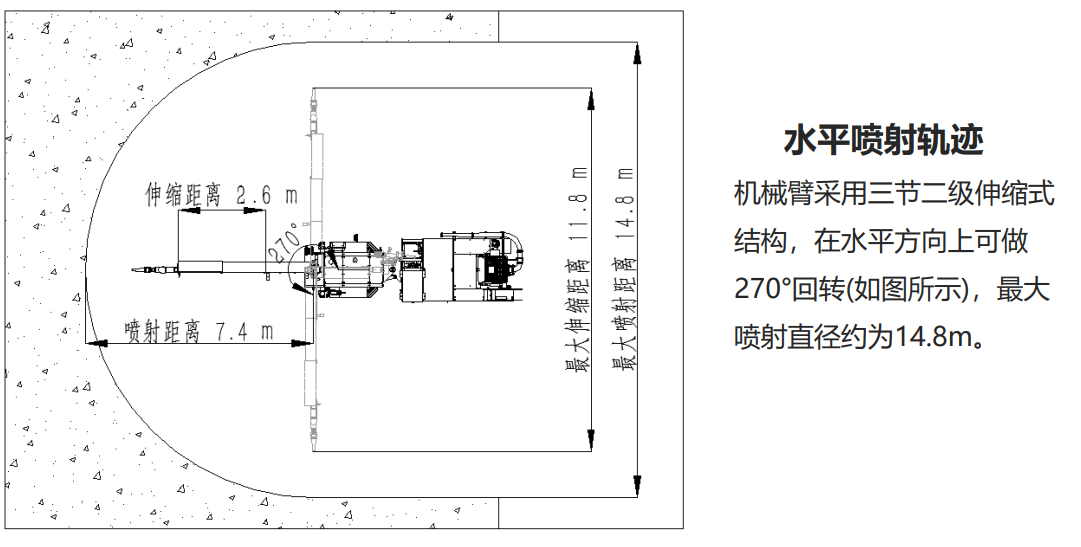

Wide Range: 2 x 7.4m wide, 8.8m high, with a 3m under-depth, this telescopic, rotary, intelligent robotic arm is specifically designed for spraying operations in narrow passageways.

High Power: The main pump is equipped with a 55kW motor, fully meeting the pumping requirements.

Zero blind spots: Intelligent jetting operation delivers high spraying accuracy, a wide spray range, and minimal spray dead zones.

Efficient Wireless Control: Wirelessly manage all spraying operations, allowing you to adjust additive ratios on the fly and improve the working environment.

Automatic adjustment of accelerating agent dosage, minimal rebound: The PLC-intelligent electro-hydraulic proportional control system for accelerating agent addition automatically matches the additive amount based on the concrete spraying rate, resulting in an even lower rebound rate during spraying.

Wide adaptability to working conditions and flexible relocation: features four-wheel four-wheel drive, articulated steering, and lateral cab positioning. The machine boasts a compact design with a small turning radius, specifically engineered for maneuvering through narrow passageways such as underground mines.

Hydraulic System

International renowned brand hydraulic control systems feature high flow rate, high pressure, efficiency, and consistently stable quality.

Equipped with a fully automatic quick-setting agent addition system, it delivers high efficiency, precision, and material savings.

It is equipped with multi-faceted safety alarms, ensuring extremely high operational safety. For instance, if the fuel level is too low, the water temperature exceeds the safe limit, or the hydraulic oil temperature becomes excessively high—any such abnormalities will trigger an audible and visual alarm notification.

Pumping System

The concrete pumping system features stable and reliable operation, long service life for wear-resistant parts, continuous material discharge, and high-quality spraying performance.

The synchronized lubrication system extends the lifespan of wear-prone components, while the use of a concrete cylinder pump ensures durable and long-lasting piston-cylinder assemblies.

High-performance robotic arm

The boom arm is made from special-grade steel, and the middle-arm joint features an enhanced design to prevent the type of failure—such as cracking—that has been reported with other manufacturers' products. Under wireless remote control, the robotic spray arm offers a wide spraying range and multiple degrees of freedom. Its dual-rotation, dual-telescoping boom structure ensures highly flexible remote operation, making it easy to precisely control spray uniformity and rebound rate. Additionally, the system delivers exceptional spraying efficiency, with smooth and fluid movements, while enabling quick and effortless extension and retraction of the boom.

The nozzle swing utilizes a spiral motor, enabling flexible, dead-angle-free rotational movements that can include axial, longitudinal, and brushing actions.

The boom of the spraying unit features a telescopic and tilting design.

PLC Intelligent Control Rapid Setting Agent System

PLC-based automated control enables precise, automatic addition of accelerators, utilizing a hose pump equipped with a frequency-conversion motor drive. Compared to screw pumps, this system offers higher accuracy in accelerator dosing, better meeting process requirements while also helping to minimize material waste.

Chassis System

A safe and reliable international-brand chassis features a powerful four-wheel, four-wheel-drive articulated design. It boasts dependable closed-loop hydraulic braking with minimal failure rates. Hydraulic controls ensure safe operation of both service and parking brakes, while maintenance is simple, straightforward, and highly dependable—resulting in very low downtime. Additionally, the system automatically engages the parking brake when oil speed reaches a certain threshold, and disengages it once the speed drops below another preset level, preventing any skidding or slipping—making it a truly safe and reliable solution.

Scope of Application

Product Specifications

| Technical Specifications of the SRSP-20 (UPS-20J) Type Jet Manipulator | Technical Specifications of the SRSP-20 (UPS-20J) Type Jet Manipulator | ||

| Maximum spray range | 8m | Bending radius | ≧R3700 |

| Jet height/Jet width | Drive | Four-wheel drive | |

| Minimum jet range | 2.5/3.3m | Driving speed | Maximum 15 km |

| Jet height/Jet width | Hill Climbing Gradient | 20° | |

| Telescoping length | 3m | Braking System | Wet-type |

| Jetting action | 6 movements (pitch, yaw, extension, retraction, and left-right rotation) | Work light | 12 units, 24V/70W HS |

| Jet nozzle | - | Cab | FOPS-certified and ROPS-certified against falling and rollover, with adjustable lateral driver seat, hydraulic suspension, and equipped with safety belts. |

| Nozzle rotates around the arm's longitudinal axis | DO Hydraulic Oil Tank | 300L | |

| Nozzle oscillating around the arm's longitudinal axis | 360° | Rechargeable battery | 2 units, 12V/80A |

| Nozzle | DN90/240° | Diesel tank | 70L |

| Jet nozzle | 10° tilt angle, 360° infinite rotation | Cable Reel | - |

| Work light | 8 hernia spotlights, 24V/45W | Operation | Automatic + Manual |

| Three-Ear Remote Control | The components can be controlled via remote control. | Cable length | 60m (standard) |

| Drive | Electric, dual operation mode (wireless/wired) | Power supply | 380V |

| Push-drive concrete pump | - | Roller diameter | 1000mm |

| Form | Dual-piston, hydraulically driven | Weight | 11T |

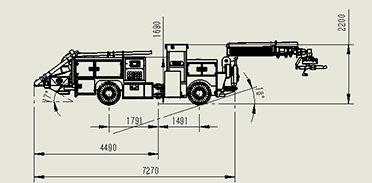

| Maximum spray rate (theoretical value) | 20 m³/h | Overall vehicle dimensions (length, width, height) | 7200mm × 1800 × 2200mm (excluding the 7200mm boom) |

| Concrete pump cylinder bore | 160mm | Additive Metering Pump – Synchronized with Concrete Pumping | |

| Maximum concrete delivery pressure | 65bar | Adjustment range | 50-600L/h |

| Maximum Aggregate Size | 16mm | Maximum working pressure | 7.5bar |

| Material receiving height | 1280mm | Additive Container | 200L |

| Motor power | 55KW | Control System | PLC |

| Power supply | 380V | High-pressure cleaning water pump | |

| Three-ear articulated off-road chassis with four-wheel drive | - | Maximum Pressure | 140bar |

| Engine | Four-cylinder turbocharged diesel engine | Traffic | 10.8L/min |

| Engine power | 96KW | Water pipe | 15m |

| Engine emissions | Meet China IV Emission Standards | Air compressor | |

| Transmission system | Static Hydraulic Transmission | Maximum working pressure | 7.5bar |

| Maximum Airflow | 9.5 m³/min | Maximum Airflow | 9.5 m³/min |

| Turning | Center-hinged, hydraulic cylinder power steering | - | - |

Online consultation