Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

Mining Rock Drilling Rig SRZY-20J

Classification:

Key words:

Product Details

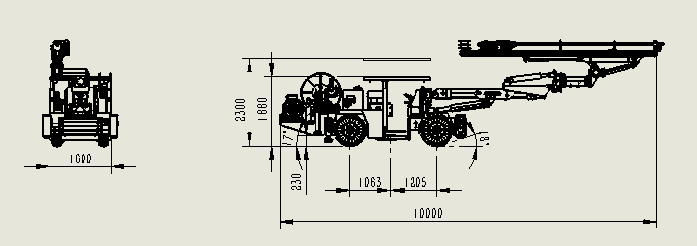

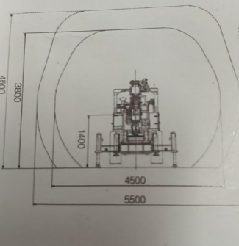

The SRZY-20J mining safety model CYTJ45 and CYTJ45(D) is a brand-new, compact mining rock-drilling device specifically designed for narrow-gauge mine tunnels. It’s ideal for rapid drilling operations in tunnel blast holes—tasks commonly encountered in underground mines, hydroelectric projects, and water diversion systems. This machine features a dual-power system, with its working mechanism fully powered by hydraulics, ensuring fast drilling speeds while maintaining low energy consumption. Meanwhile, a diesel engine provides power for locomotion, enabling the equipment to move swiftly in and out of the work area with remarkable agility. The drilling system includes advanced features such as automatic anti-jamming protection and automatic bit-retraction upon completion of drilling, enhancing both operational efficiency and safety. Overall, the machine boasts a compact design, a low center of gravity, and excellent stability, significantly improving both safety assurance and productivity while reducing operator fatigue. **Applicable Range:** 2.3 x 2.3 m to 5.5 x 4.5 m

Product Features

Well-known brand high-power rock drill

To account for the rock mass structure and drilling performance, our company offers a variety of well-known international-brand rock drill configurations for customers to choose from. The standard configuration includes the Wirth A18D/L, with higher-power rock drills available as an option. These high-powered drills deliver faster drilling speeds, enabling higher drilling rates, reducing cycle times, extending tool life, boosting overall productivity, and ultimately lowering drilling costs.

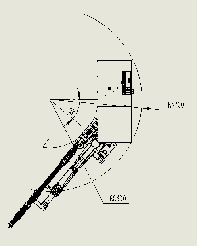

Robust translational drilling arm

Match a reliable, fully hydraulic, reciprocating, level drilling arm;

It can directly, quickly, and accurately locate positions, featuring a function that ensures the advancing beam remains parallel in all directions—particularly facilitating precise control of hole spacing during straight-hole stemming, thereby achieving superior blasting results.

Time-saving and easy to operate: No manual calibration required—simply parallel and straightforward to use; enhances tunnel shaping quality.

Compact design

Low-profile, compact structural design allows for a clearance height of just 2 meters—perfect for seated operation—and can be used in aisles as narrow as 2.3 meters. The entire machine measures only 1.39 meters wide and stands 1.9 to 2.4 meters tall, with a turning radius of just 2.4 meters. Its four-wheel, four-wheel-drive articulated chassis further enhances its exceptional maneuverability and off-road capability.

Hydraulic Control Lift-and-Lower Cab

Compliant with FOPS (Falling Object Protective Structure) requirements, the hydraulic cylinder controls lifting and lowering, ensuring smooth passage through low-height alleyways.

Safe hydraulic cable reel

The cable reel features a hydraulic automatic cable-winding system, which uses a coordinated low-cable-tension directional control valve assembly to manage cable retraction and extension. This minimizes cable friction, extending the cable's lifespan. The vehicle-mounted, flame-retardant cable measures 60 meters in length.

Wear-resistant aluminum alloy propeller assembly

The lightweight propulsion beam is made from aluminum alloy through compression molding, offering high bending and torsional strength with an extended service life. The surface of the propulsion beam is covered with stainless steel sheets, while wear-resistant PTFE (solid lubrication blocks) pads are used between moving components, eliminating the need for additional lubrication.

Double-layer slide rail propulsion beam (optional)

Double-layer slide structure: The propulsion beam is retractable—when advancing and drilling blast holes, it extends to reach deeper into the rock; when retracted, the beam shortens, making it suitable for anchor rod operations.

When adopting the scalable chute design: the tunneling hole and anchor bolt hole serve dual purposes with a single machine, and it also facilitates short-face excavation and rock drilling.

| Project (Long/Short) Parameter Values |

mm |

| Drill pipe specifications |

3090/1830 |

| Hole Depth |

2750/1550 |

| Promote Chief Engineer Liang |

4561/3611 |

Also, drill rod specifications can be customized according to your needs.

Safe and Efficient Walking Chassis System

Equipped with internationally renowned brand travel motors, a hydrostatic system, four-wheel-drive mobility, and articulated steering, the machine is powered by a diesel engine from a well-known brand. With its robust four-wheel drive and tire-based locomotion, it boasts an impressive climbing capability of up to 14°, ensuring exceptional off-road performance and allowing the vehicle to maneuver effortlessly and nimbly through narrow passageways.

The braking system uses hydraulic control and features a wet-type brake.

The vehicle’s central hinged structure features a turning radius of just 2.4/4.8 meters and a ground clearance of 250mm, giving the entire vehicle exceptional off-road capability and allowing it to maneuver nimbly and effortlessly through narrow alleyways.

Equipped with an emergency stop button switch, the rear axle features a 6-degree swing angle to adapt to uneven road surfaces, enhancing stability.

Product Specifications

| Technical Specifications of SRZY-20 (CYTJ45) Rock Drilling Rig | |

| Control System | |

| Direct Hydraulic Control System | |

| Function | Anti-Drill Jamming |

| Chassis | |

| Engine | 96KW |

| Hinge rotation angle | ±40° |

| Hydrostatic Power Steering System | |

| Hydrostatic Transmission | Four-wheel drive |

| Tire | 8.25–15 |

| Approach angle | 18° |

| Departure angle | 17° |

| Hydraulic front landing gear | 2 (extendable) |

| Hydraulic rear support leg | 2 units |

| Parking brake | |

| Fuel tank | 80L |

| Rechargeable battery | 120A |

| Electrical system voltage | 12V |

| Vehicle Lighting | 4 |

| Centralized lubrication system, exhaust catalytic converter, muffler, fire extinguisher, pneumatic grease gun, car wash water gun | |

| Climbing ability is less than or equal to | 14° |

| Walking speed | 12Km/H |

| Horn, warning lights, and reversing beeper | |

| Control System | |

| Direct Hydraulic Control System | |

| Function | Anti-Drill Jamming |

| Hydraulic System | |

| Hydraulic pump | Used for impact, positioning, and propulsion, it is employed for unloading and initiating the operation of a rotary oil pump. |

| Maximum system pressure | 230bar |

| Hydraulic oil tank | 300L |

| Low Fuel Level Indicator | With a shut-off function, located in the fuel tank |

| Oil temperature gauge, temperature switch | |

| Filtration accuracy | 10um |

| Hydraulic Oil Water Cooler | |

| Manual Oil Pump | |

| Mineral-based hydraulic oil | Mineral-based hydraulic oil |

| Technical Specifications of SRZY-20 (CYTJ45) Rock Drilling Rig | |

| Water System | |

| Water pump | Centrifugal pump |

| Motor power | 3KW |

| Maximum Flow | 70L/min |

| Maximum working pressure | 25bar |

| Air Compressor System | |

| Air Compressor Types | Screw rod |

| Motor power | 5.5KW |

| Maximum displacement | 0.7 m³/min |

| Work stress | 8bar |

| Electrical System | |

| Total Installed Power | 83KW |

| Main motor power | 75KW |

| Voltage | 380V |

| Frequency | 50HZ |

| Startup Method | Star-Delta |

| Motor Overheat Protection | |

| Battery charger | 300W |

| Transformer | 300VA |

| Cable Reel Capacity | 60m |

| Drill arm | |

| Promote compensation | 2000mm |

| Parallel Maintenance | All-round |

| Promote beam flipping | 360 |

| Rock drill | |

| Model | A18D/L |

| Drill bit | T38 |

| Aperture | 33-76 |

| Maximum impact frequency | 60HZ |

| System pressure | 230bar |

| Rotary System | 230 |

| Rotational speed | 215 |

| Maximum Torque | 1000N.m |

| Promote Liang | |

| Model | TF12R |

| Total Length | 5558mm |

| Drill pipe length | 3700mm |

| Drilling depth | 3400mm |

| Weight (including rock drill) | 575Kg |

| Propulsive force | 15KN |

Online consultation