Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

Single-arm tunneling rock-drilling carriage

Classification:

Key words:

construction machinery

Product Details

8. 88/110 kW diesel engine with powerful performance—achieving a maximum ground speed of at least 14 km/h and capable of climbing slopes of up to 14° or more. A high-altitude engine option is also available.

Equipped with hydraulic cylinders from world-class manufacturers, ensuring reliable performance and superior efficiency of the hydraulic system; featuring four-wheel drive, an articulated chassis, a fixed front axle with a swinging rear axle—this design guarantees optimal tire contact even on rugged terrain, providing exceptional road adaptability, rapid relocation capabilities, and outstanding climbing ability. The machine also boasts a two-speed hydrostatic transmission system with forward and reverse gears, offering high reliability, ease of operation, and smooth, efficient movement across flat surfaces, while seamlessly switching between two distinct torque modes—low-speed for steep climbs and high-torque for demanding uphill tasks. Additionally, it’s fitted with a 18kW-rated hydraulic rock drill powered by the renowned Wirth brand, complete with a dual-buffer system that reduces consumable wear by up to 30% compared to single-buffer systems. The drill features a high-frequency, high-pressure impact mechanism, delivering unmatched breakout force—making it especially ideal for working in hard-rock environments like mines and quarries. This results in exceptional drilling efficiency, immense impact power, and robust rotational torque, enabling faster drilling speeds and significantly boosting overall equipment productivity. Finally, the machine incorporates precision-engineered, imported alloy components, ensuring superior lubrication of moving parts through advanced aerosol-based oil mist lubrication, complemented by strategically placed oil-gas interfaces at critical points.

The cab features a retractable roof, meeting the dual spatial requirements for both transportation and construction tasks. It also complies with FOPS (Falling Object Protective Structure) standards, ensuring operator safety. Equipped with four heavy-duty hydraulic outriggers and an H-shaped front-and-rear support structure, the machine delivers exceptional mobility—while maintaining rock-solid stability even during drilling operations.

Product Features

1. The aluminum alloy propeller is highly adaptable, delivers strong thrust, is easy to operate, offers excellent stability, and requires low maintenance costs.

2. Equipped with an 18kW effective-power hydraulic rock drill, this machine delivers high operational efficiency, substantial impact force, and strong rotational torque, enabling rapid drilling and significantly boosting the overall construction efficiency of the vehicle.

3. 750mm height-adjustable canopy cab, meeting the dual spatial requirements for both transportation and construction.

4. World-class touchscreen displays device status and fault conditions in real time, making operation smarter and more user-friendly.

5. The electrical system features imported brand components, with an IP67-rated controller managing the output. It includes advanced protection mechanisms such as overcurrent, overload, phase-loss, and overheating safeguards, ensuring enhanced energy efficiency and superior safety.

6. The drill rig is protected by four alarm systems—low water pressure, low air pressure, low hydraulic oil level, and low lubricant level—ensuring worry-free operation.

7. The hydraulic system benefits from enhanced stability thanks to the use of a main oil pump from the international brand Danfoss, along with valve assemblies from world-class brands such as Eaton and Rexroth.

8. 88/110 kW diesel engine with powerful performance—achieving a maximum ground speed of at least 14 km/h and capable of climbing slopes of up to 14° or more. A高原 (high-altitude) engine option is also available.

9. Four-wheel drive, articulated chassis, with a fixed front axle and a rear axle that swings—this design ensures optimal tire contact even on rough terrain, providing excellent road adaptability and enabling rapid relocation.

10. Four heavy-duty hydraulic outriggers—featuring an H-shaped front-and-rear structure—ensure exceptional mobility, while providing a remarkably robust "chassis" during rock drilling operations.

11. Utilizing hydraulic cylinders from world-class manufacturers ensures a reliable and high-performing hydraulic system.

12. The patented positioning arm system allows for quick and flexible positioning. When adjusting the rock-drilling arm’s pitch and left-right orientation, a unique industry-leading patented technology ensures precise, full-range parallel maintenance of the advancing beam, effectively controlling hole spacing and inter-hole parallelism—thereby enabling accurate management of over- or under-excavation and maintaining smooth tunnel profiles.

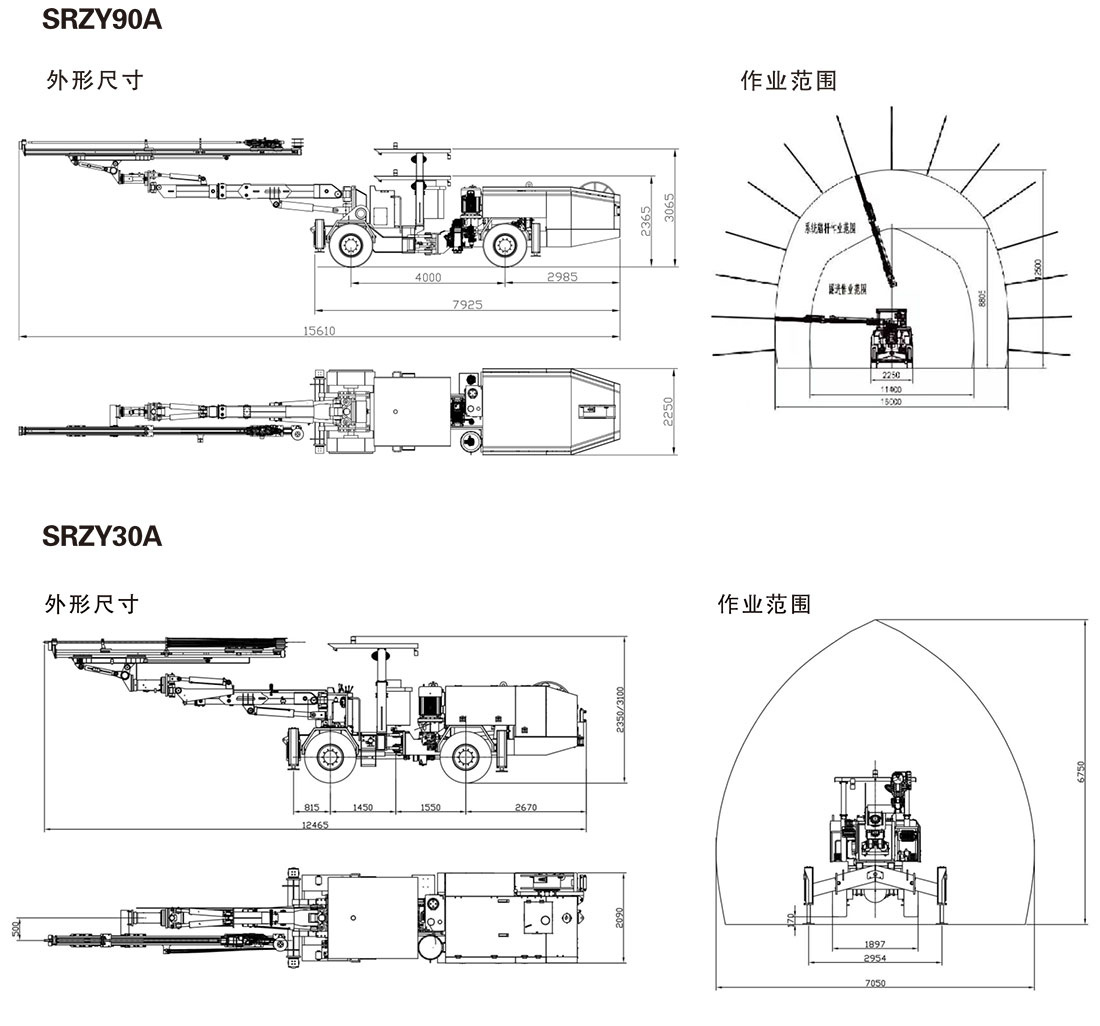

Product Specifications

| Name |

Project |

SRZY90A |

SRZY30A |

|

| Whole-machine parameters |

Overall machine dimensions: mm |

15610 × 2250 × 2365 ÷ 3065 |

12465 × 2090 × 2350 ÷ 3100 |

|

|

Scope of the assignment |

Horizontal tunneling mm |

11,400 × 8,700 |

7050 × 6750 |

|

| Radial anchor bolts mm |

16,000 × 12,500 |

10,000 × 9,700 |

||

| Drill hole diameter mm |

φ43 to φ76 |

φ43 to φ76 |

||

| Drill rod length mm |

3700/4300/4900/5525 |

3700/4300/4900 |

||

| Drilling depth mm |

3400/4000/4600/5200 |

3400/4000/460C |

||

| Drilling speed m/min |

0.8–2 |

0.8–2 |

||

| Main motor power, kW |

55/75 (Plateau Type) |

55 |

||

| Hydraulic oil tank capacity: L |

210 |

210 |

||

| Total weight: kc |

21000 |

14500 |

||

| Drill Arm Parameters |

Rock drill model (optional) |

1838ME/2238 |

1838ME/2238 |

|

| Impact power kW |

18 out of 22 |

18 out of 22 |

||

| Work stress hits the bar |

220 |

220 |

||

| Impact frequency Hz |

60/73 |

60/73 |

||

| Rock drill rotation speed r/min |

0-215 |

0-215 |

||

| Rotation ° |

±180 |

±180 |

||

| Propeller pitch |

-3/90 |

-3/90 |

||

| Stretchable mm |

1800 |

1500 |

||

| Propeller compensation mm |

1800 |

1250 |

||

| Chassis System Parameters |

Diesel engine power in kW |

110 |

88 |

|

| Turning° |

±40° |

±38° |

||

| Rear axle steering angle ° |

±7° |

±7° |

||

| Approach/Departure Angle ° |

25/16 |

21/14 |

||

| Minimum turning radius: m |

Inner > 4.3, Outer > 9 |

Inner > 3.6, Outer > 5.9 |

||

| Walking speed km/h |

14 |

13.5 |

||

| Climbing angle ° |

14 |

14 |

||

| Minimum ground clearance: mm |

304 |

300 |

||

| Service brake |

Dry/wet |

Dry/wet |

||

| Fuel tank capacity: L |

110 |

60 |

||

| Gas Supply System Parameters |

Flow rate L/min |

900 |

700 |

|

| Motor power: kW |

7.5 |

3 |

||

| Working Pressure Bar |

8 |

8 |

||

| Water Supply System Parameters |

Flow rate L/min |

75 |

70 |

|

| Motor power: kW |

3 |

3 |

||

| Working Water Pressure Bar |

0.8–1.2 |

0.8–1.2 |

||

| Electrical System Parameters |

Total motor power in kW |

65.5/85.5 |

61/(55 + 3 + 3) |

|

| Supply voltage V/Hz |

380 divided by 50 |

380 divided by 50 |

||

| Vehicle Lighting Lamp W |

8 × 48W |

8 × 48W |

||

| Work Lighting Lamp W |

2 × 300W |

2 × 300W |

||

| Cable reel capacity m |

70 |

70 |

||

Note: Due to varying customer needs, our company reserves the right of final interpretation for the above content.

Device View / Job Scope

Online consultation