Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

SRG312A Arch Support Cart

Classification:

Key words:

Product Details

Product Introduction

1. Full Operating Conditions: The system is capable of performing arch-support operations for tunnel excavation using three bench methods (full-face, two-bench, and three-bench techniques). This capability is made possible by its unique foldable + telescopic boom structure, which allows the arch-support device to extend deep into the three-bench section for precise installation of the arch framework.

2. High Efficiency: Multiple arch supports can be transported into the tunnel on the same vehicle and installed in one go. During three-stage construction, the main boom operates across all three stages, while the two auxiliary booms simultaneously handle the installation of arch supports for the middle stage. It takes only 1 hour to complete the installation of two arch supports—one each for the three-stage and middle-stage sections—making this method significantly more efficient than manual labor or current arch-support machines available on the market.

3. High Efficiency: The equipment requires only 2 to 3 workers to complete the entire arch-erection process, significantly reducing labor costs compared to traditional manual arch-support methods—and truly enabling mechanized construction operations. Meanwhile, it can simultaneously handle work at two tunnel faces, delivering substantial economic benefits and social value to construction companies.

4. High Safety: The equipment features wireless remote control operation, allowing operators to work beneath the initial spray surface, thereby enhancing personnel safety.

5. Intelligent Design: The entire machine features a digital system designed with an industrial controller and sensor technology, along with a user-friendly human-machine interaction system. This ensures superior control performance and enables real-time monitoring of the system's operational status.

6. The SRG312A Tunnel Multi-Functional Arch Support Installation Carriage is a new type of equipment designed for constructing tunnel support systems using either the full-face or step-by-step methods, as well as installing rock bolts and mesh. Additionally, equipped with a suspended platform, it can also serve multiple purposes, such as quality inspection, providing an elevated work platform, performing grouting, loading explosives, and facilitating efficient bolt installation at height. Featuring a three-arm, three-robotic-arm configuration paired with three suspended platforms, each arm enables automatic arch support gripping and precise micro-adjustments at the robotic end, allowing for highly efficient upright arch installation—truly making mechanized construction operations a reality.

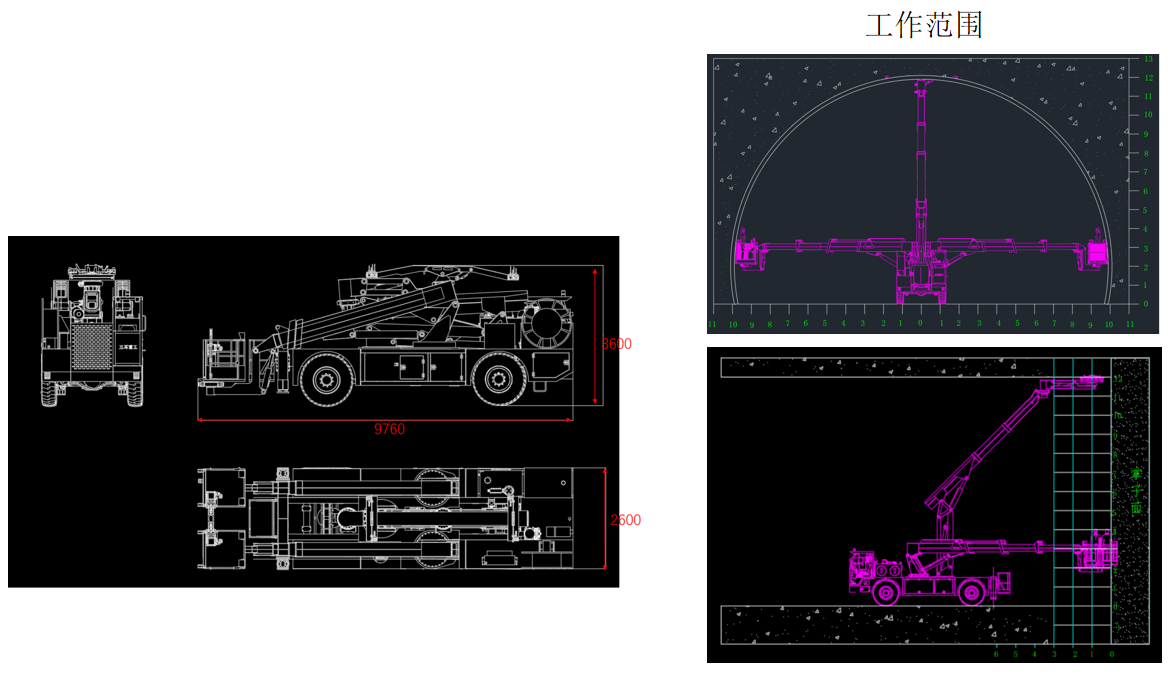

Product dimensions and installation schematic

Product Specifications

| Project Name |

Specification Model |

Parameters |

| Complete machine |

Product Model |

SRG312A |

| External dimensions mm |

9200×2600×3500 |

|

| Maximum working height |

12m |

|

| Maximum job width |

15m |

|

| Drive and steering method |

Four-wheel drive, four-wheel steering |

|

| Overall machine quality |

25000kg |

|

| Minimum turning radius |

Inner side: 2.3 m / Outer side: 7.5 m |

|

| Climbing ability |

15° |

|

| Walking speed |

0–15 km/h |

|

| Ground clearance |

400mm |

|

| Engine |

Type |

Six-cylinder water-cooled diesel engine |

| Rated Power |

125KW/2200rpm |

|

| Boom arm |

Arm boom quantity |

3 aircraft |

| Maximum main boom extension length |

12m |

|

| Maximum Lifting Capacity |

3000kg |

|

| Main Arm Pitch Angle |

-30, 59° |

|

| Maximum installation height |

12m |

|

| Left and right auxiliary arm maximum extension length |

13m |

|

| Maximum Lifting Capacity |

600 + 200 |

|

| Pitch angle of the main arm |

-17, 48° |

|

| Rotation angle |

0.45 |

|

| Hydraulic |

Motor power |

55KW |

| Main oil pump displacement |

100ml |

|

| Other |

Equipped with a cable reel, chassis with emergency handling capabilities, and a three-arm system with remote control. |

|

Note: Due to varying customer needs, our company reserves the right of final interpretation regarding the above content.

Construction Site Display

Online consultation