Products

Contact Us

Domestic:86-133-9741-6525

International: 86-157-7384-5032

(Wechat/Whatsapp/Skype)

E-mail:srzgnifty@gmail.com

Address: Sany Supporting Industrial Park, Economic and Technological Development Zone, Loudi City, Hunan Province

Y10 Hydraulic Spray Machine

Classification:

Key words:

construction machinery

Product Details

The soil spraying machine is a professional equipment applied to greening. Through this equipment, the planting soil is mixed with water in a mixing container to form a mixed slurry, and it is sprayed on the slope to be sown by pipeline and wind compression.

The guest soil spraying machine is used in greening projects such as high-speed public (railway) road slope greening, mountain surface greening, landfill without soil coverage, mine greening desert negotiation, river embankment protection, large-scale green space reconstruction, etc.

The series of products independently developed by Saner Heavy Industry not only have the excellent characteristics of low cost, high safety, convenient construction, independent operation of the whole machine, convenient movement, etc., but also can be developed, designed and manufactured according to the needs of customers. The related auxiliary equipment, from raw materials to construction, is in place, making the construction more convenient, time-saving, and labor-saving. Saner's soil spraying machine is deeply loved by customers, get the majority of users praise, three ear guest soil spraying machine-a good helper of China's greening.

Product advantages

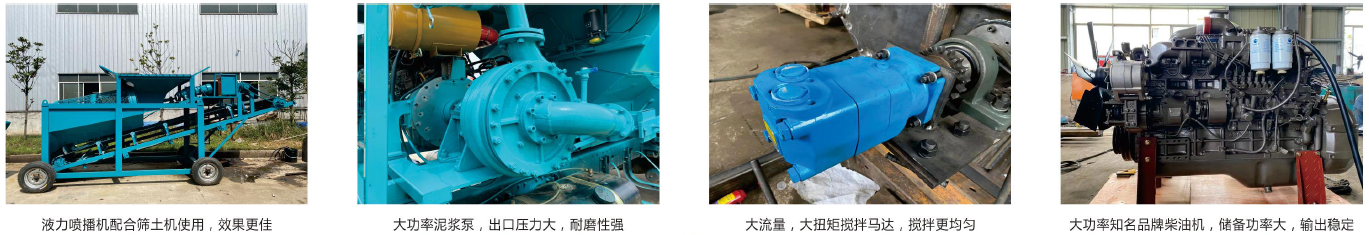

1. High spraying efficiency: The domestic high-power six-cylinder turbocharged diesel engine drives the mud pump to spray the large-flow gear pump to drive the mixing, the power output is more sufficient, and the operation efficiency is higher.

2. Good fuel economy: When not spraying slurry, the diesel engine is in the total speed state to drive the gear pump to drive the stirring motor, which can meet the stirring speed requirements and reduce diesel engine fuel consumption. Achieve fuel economy.

3. The engine power output is more sufficient: The domestic high-power six-cylinder turbocharged diesel is used as the power output, with large output power, large reserve power, and large output torque, which fully guarantees the mud pump power and mixing power output.

4. Mud pump has good passability and is not easy to be blocked: large diameter, wide blade impeller has better passability when spraying pure mud, fiber and mud mixture.

5. Low cost of later use: the structure of the mud pump is simpler, and the replacement cost of later parts is lower,

Product Parameters

| Product Name |

Product Model |

Product abbreviation |

Product Name |

Product Model |

Product abbreviation |

||

| Hydraulic soil spraying machine |

YP08-24-176RS |

Y10 |

Hydraulic soil spraying machine |

YP08-26-191RS |

Y11 |

||

| Serial Number |

1 Whole machine parameters |

Serial Number |

1 Whole machine parameters |

||||

| 1 |

Overall size (mm) |

5280 × 2400 × 2400 |

1 |

Overall size (mm) |

6000 × 2400 × 2400 |

||

| 2 |

Rated weight (t) |

Approximately 3.55. |

2 |

Rated weight (t) |

Approximately 3.85. |

||

| 3 |

Nozzle form |

single gun head jet |

3 |

Nozzle form |

single gun head jet |

||

| 4 |

Maximum vertical spray distance (m) |

60 |

4 |

Maximum vertical spray distance (m) |

70 |

||

| 5 |

Maximum spray distance along the slope (m) |

80 |

5 |

Maximum spray distance along the slope (m) |

100 |

||

| Serial Number |

2 pumping parameters |

Serial Number |

2 pumping parameters |

||||

| 1 |

Working driving mode |

Diesel engine |

1 |

Working driving mode |

Diesel engine |

||

| 2 |

Rated power (kw) |

176 |

2 |

Rated power (kw) |

191 |

||

| 3 |

Rated speed (r/min) |

2600 |

3 |

Rated speed (r/min) |

2600 |

||

| 4 |

Hopper volume (m³) |

8.0m³ |

4 |

Hopper volume (m³) |

8.0m³ |

||

| 5 |

Theoretical outlet pressure (Mpa) |

24 |

5 |

Theoretical outlet pressure (Mpa) |

26 |

||

| 6 |

Transmission mode |

electromagnetic clutch transmission |

6 |

Transmission mode |

electromagnetic clutch transmission |

||

| 7 |

Maximum theoretical flow (m³/h) |

80 |

7 |

Maximum theoretical flow (m³/h) |

80 |

||

| 8 |

Maximum solid content |

Volume ratio 30%, weight ratio 50% |

8 |

Maximum solid content |

Volume ratio 30%, weight ratio 50% |

||

| 9 |

Maximum particle diameter (mm) |

25 |

9 |

Maximum particle diameter (mm) |

25 |

||

| 10 |

Material (overcurrent part) |

wear resistant high strength steel |

10 |

Material (overcurrent part) |

wear resistant high strength steel |

||

| 11 |

Stirring mode |

Horizontal shaft inclined slurry hydraulic mixing |

11 |

Stirring mode |

Horizontal shaft inclined slurry hydraulic mixing |

||

| 12 |

Stirring direction |

Clockwise/Counterclockwise |

12 |

Stirring direction |

Clockwise/Counterclockwise |

||

| 13 |

Stirring shaft speed (r/min) |

≤100 |

13 |

Stirring shaft speed (r/min) |

≤100 |

||

| 14 |

Lubrication system |

Progressive oil distribution type, manual |

14 |

Lubrication system |

Progressive oil distribution type, manual |

||

| 3. walking mode |

3. walking mode |

||||||

| Walking mode |

Onboard |

Walking mode |

Onboard |

||||

Online consultation